CO2 Lasers

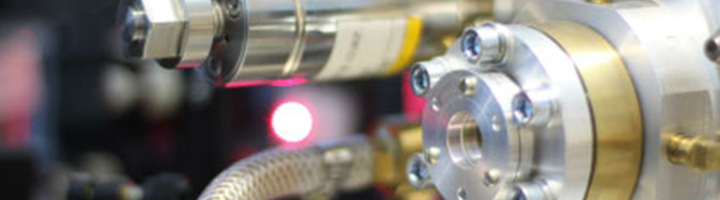

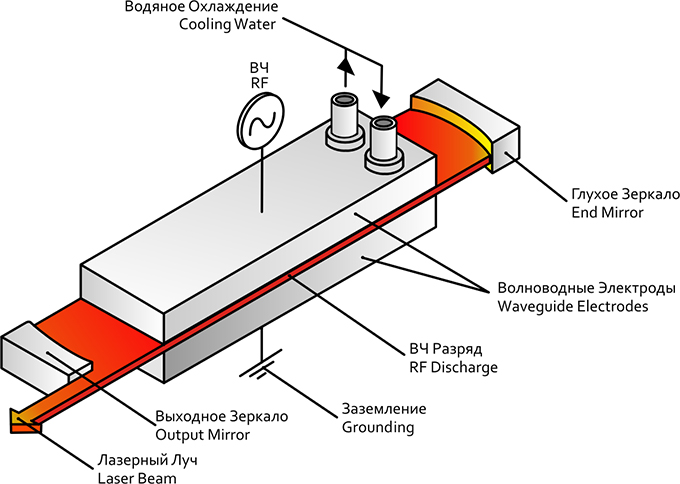

One can see now the fast growth of production and purchase of gaseous lasers with the diffuse cooling of active medium at the market of lasers for material processing. The following trends are currently apparent in the development of these lasers: reduction in the weight and size while retaining the power and quality of the output radiation, increase in the reliability, and reduction of the cost. One has to note that from this point of view the fast-flow lasers have already exhausted their potential – they are rather expensive and bulky, because contain the gasodynamic ducts, pumps for gas flow and heat exchangers. The seemingly contradictory market requirements direct the developers onto the way of transition from the fast-flow lasers to the new technologies, based on the diffuse cooling of active medium (AM). This has meant intensive work on laser operating at higher (60-150Torr) pressures of active medium, which is radio-frequency (RF)-pumped at frequencies ranging from tens of MHz to several GHz. The use of RF pumping improves the stability and homogeneity of the discharge glow. The specific energy delivery to the RF discharge in dozen times exceeds the values for the DC discharge. In addition, for the RF discharge the regions of the potential drop near the electrode are small and have the size of just 0.2-0.3 mm for the discharge frequency f=100 MHz. Hence, the volume of the active medium is practically equal to the discharge volume.

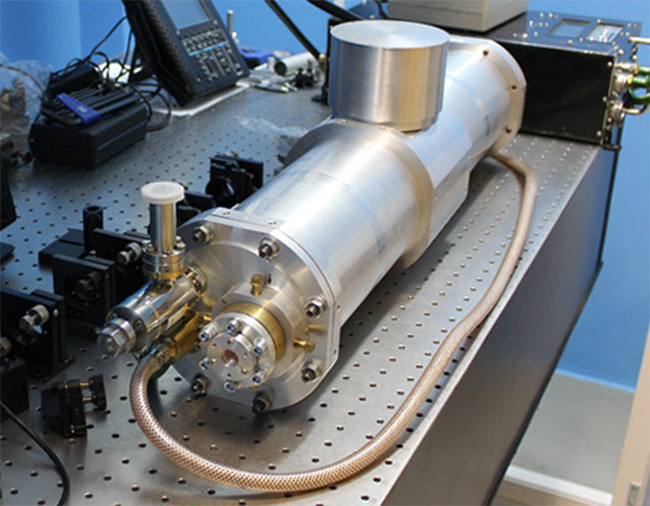

These features of the transverse RF-pumping made it possible to use a slab configuration of the discharge gap (the planar one(see Fig.) or coaxial), when the gap between the extended electrodes is only 1-5 mm. The latter, in turn, ensures the efficient removal of heat from the pumped AM by heat conduction and gas diffusion to the cooled electrodes. In this case are required the voltages (some 200-300 V), which are much lower than in the case of longitudinal RF pumping or pumping by the longitudinal DC discharge (dozens kilovolts).

Note also that the slab СО2 lasers can operate in a sealed-off mode for more than 10000 hours; they are characterized by high reliability and high optical quality of radiation (deviation from the diffraction limit is not more than 1.3 times). Last several years have brought the development in some leading world companies of the slab lasers with the radiation power up to 3 – 5 kW. High optical quality of radiation, together with the so high power, make it possible to provide fast, and even more important, high quality cut of the steel with the thickness over 10 mm, opening thus a very serious prospects for such type of lasers in metal-processing and machine-building industry.

Several distinctions of slab CO2 СО2-lasers from other type of lasers:

|

Product Catalogs of Russian Laser Systems (in Russian)